We are creative, ambitious and ready for challenges! Hire Us

Tribology Simulations Course

- Home

- Tribology Simulations Course

The course introduces participants to the theory of numerical and analytical modeling in tribology field, shows some of the common rules of thumbs and overviews the capabilities of TriboSolver. After the course participants will understand the specifics of tribology simulations, know the main analytical expressions and rules of thumb, as well as know how to use TriboSolver for problem solving.

Agenda of the course is given below.

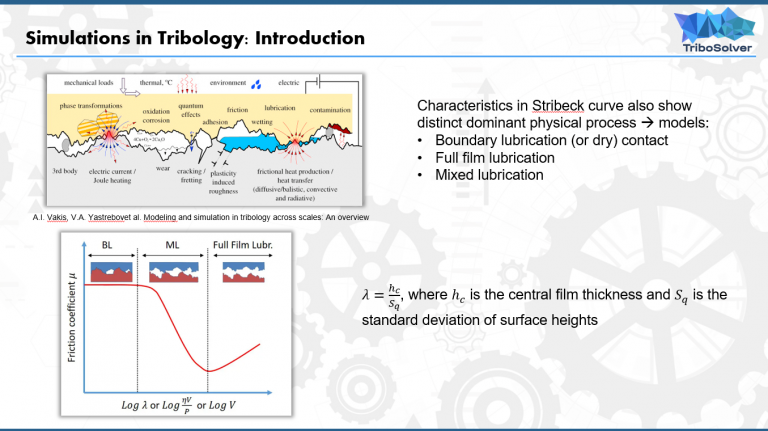

The course starts with a short introduction to the topic, history and prospects of simulations in tribology field. This part introduces the main three use cases encountered in tribology simulations:

- Dry Contacts

- Lubricated Contacts

- Mixed Lubrication

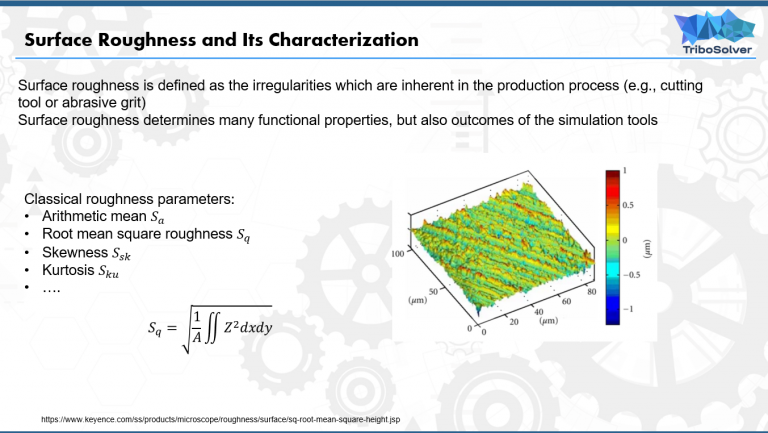

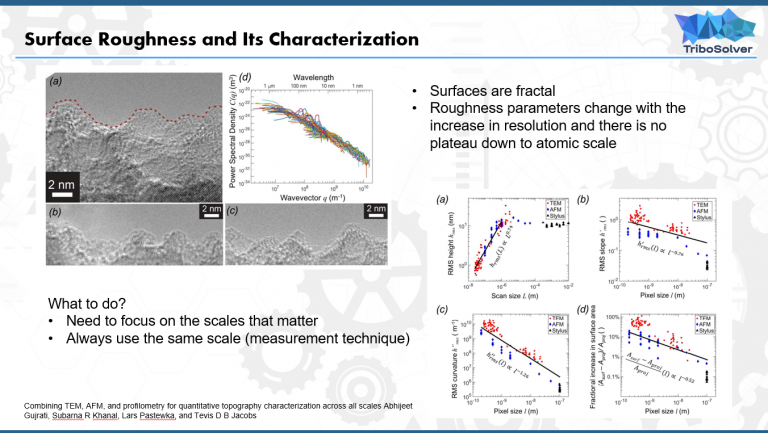

Roughness of the surfaces in contact determine the ovearall performance of the tribological system. This sections is devoted to various parameters that are used to describe the surfaces and their limitations.

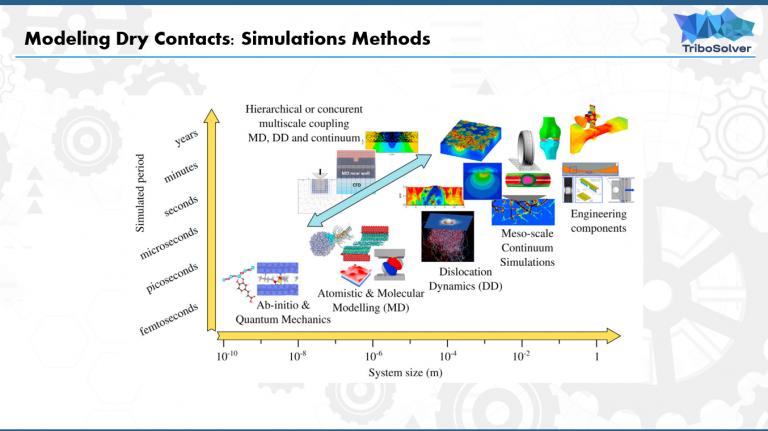

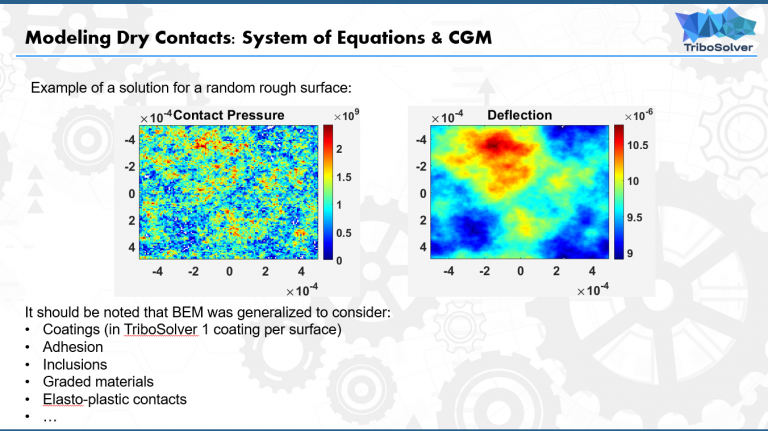

Dry Contact problems are characterized by the absence of lubricatns and thus behavior of the tribological system is determined by the surface roughness of the contacting system and the involved materials. In this section, various simulation methods and their limitations will be introduced, e.g., Molecular Dynamic Simulations, Boundary Element Method, Finite Elements and their role in tribology analysis. Most of the attention will go to the Boundary Element Method as the most widely used approach to analyse rough contacts.

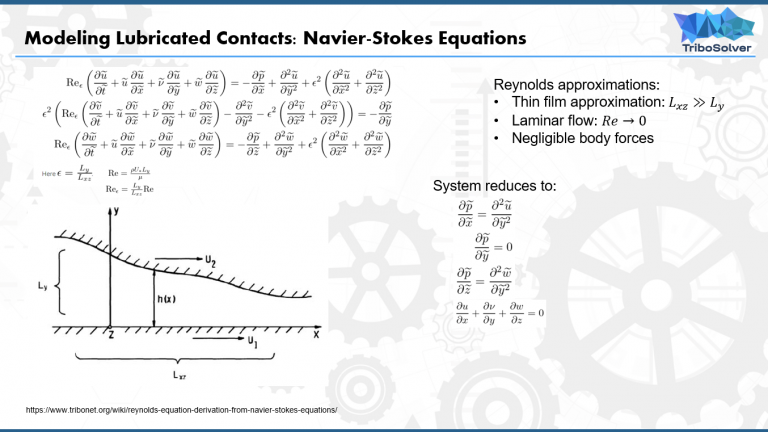

This section deals with the modeling of fully lubricated contaccts, when the rubbing surfaces are completely separated by a lubricating film. In this case, behavior of the system is determined by the lubricant properties and applied conditions. The section will introduce Reynolds equation and its derivation, as it is fundamental equiation of tribology.

Finally, mixed lubrication problem is introduced in this section. This set of problems is described by the situations when surface roughness and the lubricant film both play a significant role in the behavior of the system.

This section introduces wear modeling approaches used in the field of tribology, such as Arcahrd Wear model.

Once the theoretical part is completed, the course introduces the user to TriboSolver, its history and its capabilities.

In this section, dry contact analysis is performed using TriboSolver. Subsurface stress analysis of uncoated and coated surfaces are considered, as well as contact pressure and contact area claculations.

Course participants explore TriboSolver capabilities in solving Elastohydrodynamic equations and use of semi-analytical approaches to calculate central film thickness.

This section addresses application of TriboSolver to mixed lubrication problems.

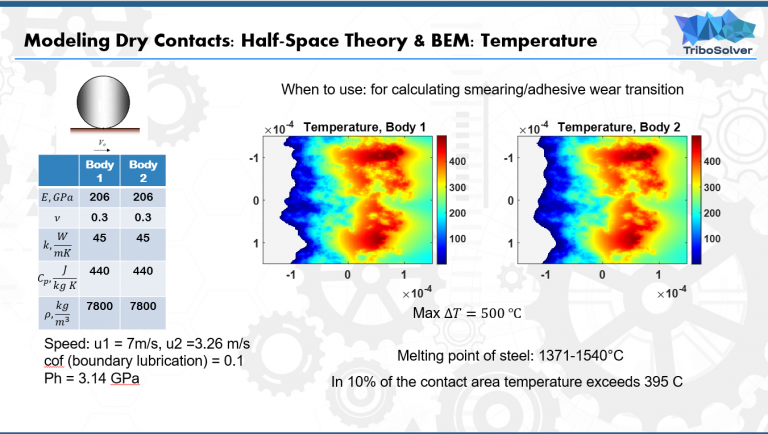

Modeling contact temperature is important and can be perfromed for dry as well as mixed lubricated contacts. Contact temperature is known to determine transition from mild to severe adhesive wear in mixed lubricated contacts and thus must be calculated.

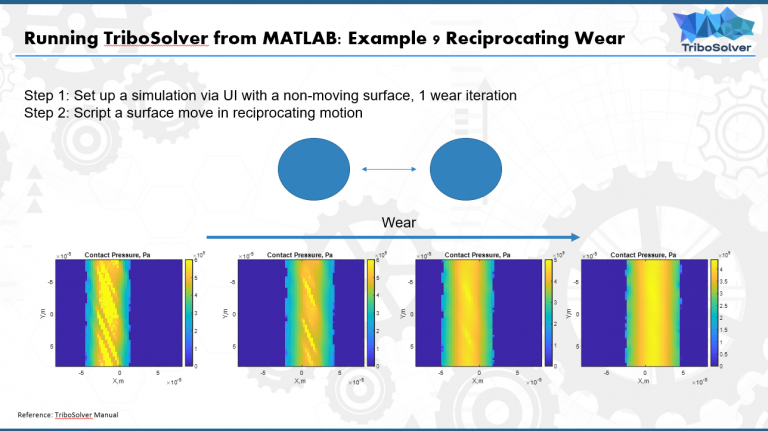

Modeling wear is another capability of TriboSolver that is introduced during the course.

Finally, several practical moments of using TriboSolver are introduced, e.g., running TriboSolver from MATLAB or python, TriboSolver manual, Inputs and Outputs of the simulator.